What’s more, it is harder to find a technician who knows their way around a CVT than one who knows about more conventional transmission systems. If the driving experience is important to you, it is probably best to avoid CVTs.ĬON: although upkeep and running costs of a CVT are often relatively low, actual repairs can do lethal damage to your bank account. Since it is designed to be useful and efficient, it thoroughly feels the opposite of a sporty shifter. Thanks to its gear-less and smooth shifter design, you can move seamlessly from idle to peak power.ĬON: arguably, the most critical disadvantage of a CVT is its lack of fun. In fact, you don’t need to worry about gears at all. PRO: with a CVT, you no longer need to worry about awkward and rough gear shifting.

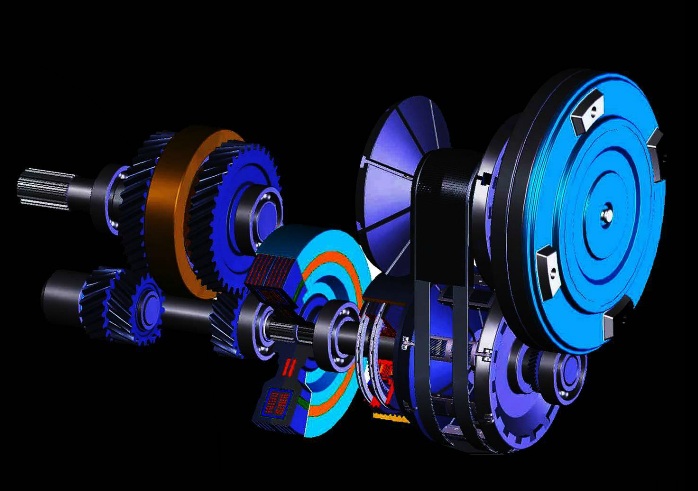

This helps reduce the size of the whole unit (advantageous for small compact cars), better performance, and a reduction in fuel usage.

Continuous variable transmission manual#

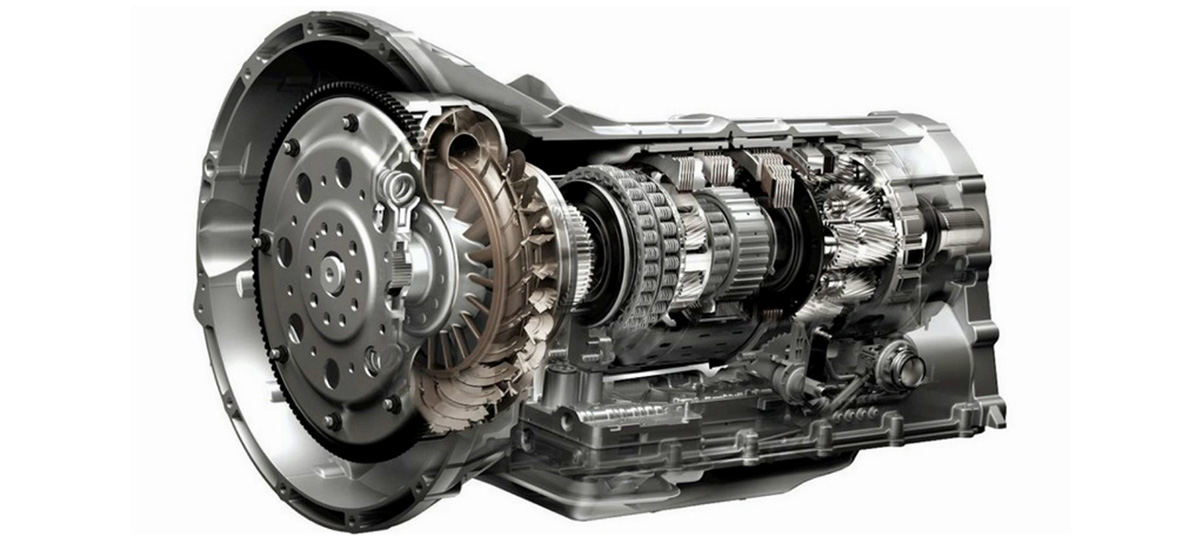

PRO: CVTs are relatively lighter and have a more compact design than a standard automatic gearbox. Continuous Variable Transmission (CVT): The major drawback with Manual Transmission system (Synchromesh Gearbox) that all gears are meshed with each other, in whatever speed the vehicle is. While the first designs failed to be as fuel-efficient as the standard gearbox, the engineers managed to evolve the sophisticated, more complex automatic transmission design to be on par with the manual transmission’s fuel efficiency and reliability. The automatic transmission was invented in 1921 by the Canadian steam engineer Alfred Horner. Unlike traditional automatic transmissions, continuously variable transmissions dont have a gearbox with a set number of gears, which means they dont have. The basis of their design is the foundation of manual gearboxes to this day.Ĭhronologically speaking, the second most commonly accepted transmission was the automatic system. The first modern manual transmission's emergence dates back to 1894 when French inventors Louis-Rene Panhard and Emile Levassor developed and demonstrated their three-speed gearbox. The first commonly accepted gearbox was what we now know as ‘manual’ or ‘standard’ gearbox. It is critical to have a firm grip on other types of transmissions before we elaborate on CVT transmissions. They might originally have been an oddity, but fuel-efficient CVTs are now here to stay.A car’s transmission job is to ensure reasonable amounts of engine power go to drive wheels at any given speed. Some automakers also add pre-set points for the variable pulley sizes, creating artificial “gears” that can make the CVT feel more like a traditional transmission, and sometimes with the driver-operated manual mode that some automatics offer. They’re always being improved, of course, and some of today’s better CVTs can be almost indistinguishable from regular transmissions under everyday driving. They don’t have the burst of power we expect on acceleration, and the sound doesn’t always equate to what the car is doing – often described as a “rubber-band feel.” They can also be noisy when mated to some lower-powered four-cylinder engines, and some of the earlier ones could have reliability issues. Quite simply, we’re not used to them, and so they can feel weird. There’s only so much they can take before a powerful engine would rip them apart – which is why it’s unlikely you’ll see one on a heavy-duty pickup truck anytime soon.Īnother issue is customer acceptance, especially in the CVT’s earlier years. So if they result in fewer trips to the gas pump, why don’t all vehicles use them? For one thing, there’s a limit to how much power they’re able to handle.

But this adds weight and complexity, as well as the need to engineer it to avoid “gear hunting,” when a transmission annoyingly switches back and forth between two gears when driving conditions change slightly, such as accelerating up an incline.īecause the CVT continually adjusts the ratio between the crankshaft and the wheels, the engine can stay at its ideal rpm for the driving conditions, building power steadily on acceleration without having to rev up and then drop down as with traditional gears. To reduce this and better keep the engine in its ideal range for power and efficiency, automakers add extra gears, sometimes as many as nine or ten. As a result, when you’re accelerating, you’ll notice the engine rpm rises (either by the sound, or by looking at the tachometer, if your vehicle has one) and then drops as the next gear kicks in. A conventional automatic transmission switches between its fixed gears as needed.

0 kommentar(er)

0 kommentar(er)